Risk-based prioritization for large organizations, regulators, and insurers who need to integrate complex systems and prevent serious incidents and fatalities.

Too much risk data, but where’s your line of sight to highest-risk activities? We declutter your metrics, integrate your systems, and build implementation-ready solutions that actually change outcomes.

From Data Overload to Actionable Insights.

Our clients see measurable improvements when they shift from fragmented metrics to integrated, risk-based prioritization.

improvement in safety performance

increase in productivity

improvement in product quality

cost benefits from more targeted interventions

Why it matters to you

Organizations with mature risk management systems and effective implementation can see valuation premiums of up to 25%. Risk-based prioritization is not just a safety strategy. It’s a business strategy.

How We Deliver Risk-Based Prioritization

We offer three service packages, each built to meet organizations at different stages of their risk management journey. Always with a focus on integration, implementation, and measurable outcomes.

VISUALIZE & PRIORITIZE

See What Really Matters

For organizations with substantial existing data but limited clarity, this package focuses on serious incident and fatality precursor identification and systems-level gap analysis. We use multi-factor analysis and data fusion to reveal hidden patterns in your incident, inspection, and operational data.

We then develop real-time dashboards and visualizations that support decision support at the executive and operational levels, highlighting your top risks and most important leading indicators.

Best for: Organizations with existing data who need focus and a clear, risk-based prioritization framework.

INTEGRATE & IMPLEMENT

Make the System Work Together

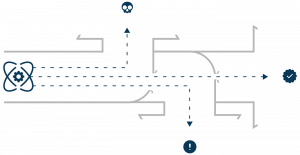

This package is designed for companies struggling with execution and system fragmentation. We support cross-functional risk system integration—EHS, process safety, operational risk, asset management, and HR into a cohesive, risk-based structure.

We develop leading indicators that connect workgroup-level performance to corporate KRIs and support implementation barrier analysis and mitigation, so critical controls and initiatives succeed in real-world conditions.

Best for: Companies with multiple systems and programs that need integration, consistent leading indicators, and practical implementation support.

DE-RISK & DEMONSTRATE

Build Confidence in Innovation

Innovation brings both opportunity and risk. We support new technology and high-hazard projects with scenario analysis, field testing, and quantitative risk assessment. From hydrogen and combined heat & power to new digital safety tools, we help you understand and control the risks before full deployment.

We then provide regulatory due diligence support and evidence packages that demonstrate risk-based prioritization and control effectiveness to regulators, boards, and external stakeholders.

Best for: Innovation projects, pilots, and large capital projects that require stakeholder confidence and defensible risk analysis.